Kick-off for the production of thermoplastic honeycomb cores in Halle

ThermHex Waben GmbH and the State Invest €1.5 Million in Production Facility

As of today, Halle is officially a production site for thermoplastic honeycomb cores. The new production facility on Merseburger Straße in Halle was ceremoniously inaugurated, with a keynote speech by the State Minister of Economic Affairs, Dr. Reiner Haseloff. He praised the highly innovative and fast-growing company as a valuable asset for both the city of Halle and the state of Saxony-Anhalt.

ThermHex Waben GmbH, which received support from the university-based startup network UNIVATIONS Saxony-Anhalt during its founding, is investing a total of around €1.5 million in the Halle location. Fifty percent of the investment is funded by the state of Saxony-Anhalt. CEO Jochen Pflug is starting production with six employees, with plans to expand the team to up to 20 in the future. The new facility in Halle is expected to produce around one million square meters of honeycomb material annually.

Since 2005, aerospace engineer Jochen Pflug has also served as the CEO of the Belgian company EconCore, a public limited company focused exclusively on research and development. ThermHex Waben GmbH is a wholly owned subsidiary of EconCore. EconCore utilizes an innovative process for the continuous production of honeycomb cores for lightweight panels, developed by Jochen Pflug in cooperation with KU Leuven. Compared to traditional, discontinuous production, the new, highly automated and uninterrupted method offers significant time and cost advantages, using approximately 30 percent less material. The technology is protected by international patents.

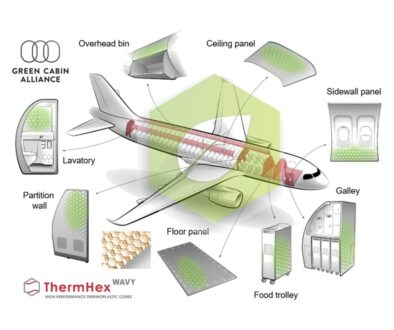

Originally developed for space applications, lightweight panels with honeycomb cores are increasingly used in various industries due to their unique properties—lightweight, low material usage, yet high stability. The sandwich structure with a honeycomb core is now found in interior and structural components of aircraft and yachts, in many automotive parts, as well as in furniture and packaging. Depending on the application, the honeycomb cores are combined with various facing materials (such as plastic or steel) to form the central layer of lightweight yet extremely rigid sandwich panels. In addition to use in flat panels—like those used for truck bodies—large quantities of thermoplastic honeycomb cores are now also processed into complexly shaped components, such as wind turbine rotor blades.

The roots of honeycomb technology can be traced back to Halle. In 1901, the Halle-based paper goods manufacturer Heilbrun & Pinner significantly contributed to the development of honeycomb cores by inventing decorative honeycomb paper and launching its automated production in 1903. The company’s products—decorative objects and cards—were primarily exported to the USA and the UK. Saxony-Anhalt was also a pioneer in applying honeycomb structures to sandwich components. In a 1915 patent, Hugo Junkers, who had moved from Aachen to Dessau, was the first to describe the advantages of honeycomb structures in lightweight yet stable components for aircraft construction.

The establishment of ThermHex Waben in Halle is not only due to the favorable location factors of the Saale city but also to the proactive support from the city’s economic development agency.

With the opening of this new production facility, Jochen Pflug is continuing the legacy of past innovations—bringing honeycomb technology back to its place of origin: Halle.